What should you know when purchasing the 3D Welding Tables?

3D welding tables is the professional platform for workpiece locating, clamping and locking. Its application range is quite widely, and it is a basic tool commonly used by machinery manufacturers. But some users don’t know how to select it. So here I will tell you some information about the knowledge of 3D welding table in appearance, quality and price when purchasing 3D welding table.

1.Material

As for the casting welding table, it made of resin sand casting iron HT300. Then followed by HT250, it is cement sand casting iron. As for the steel welding table, it made of Q345, followed by Q235.

2.Hardness

The higher the hardness of the cast iron, the more wide the range of the 3D welding table that can be used in the future. There are three main factors affecting the hardness of the three-dimensional welding table. They are the cooling rate of the raw material cast iron, the chemical composition of the material, and the manufacturing and processing methods. The faster the cooling rate, the higher the hardness, but it is also easy to cause cracks on the surface of the cast iron. So be careful when you select it.

3.Processing

What kind of machinery for 3D Welding Table processing? The surface finish and dimensional tolerances of the 3D Welding Table processed by CNC Gantry Machining Center and CNC lathe machine are different.

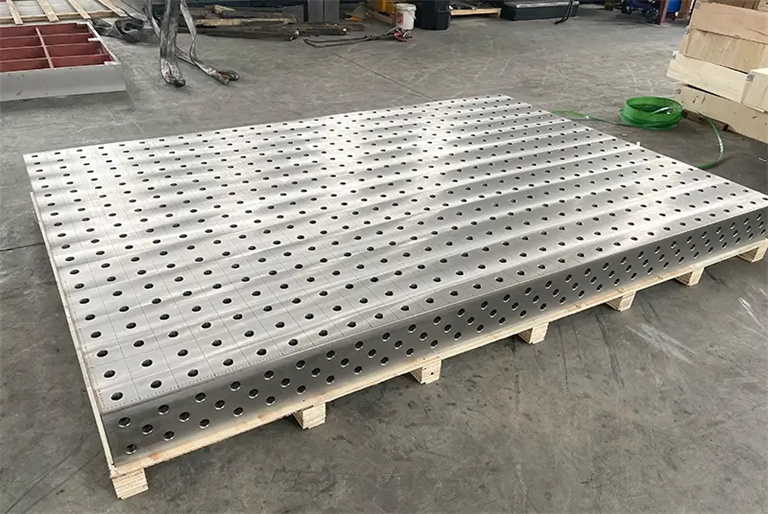

4.Thickness

There is basically no difference in the thickness of the steel type welding table. As for the casting type welding table, as usual, we processed it to 30mm in thickness, and then process the hole depth to 24-27mm with the counterbore.

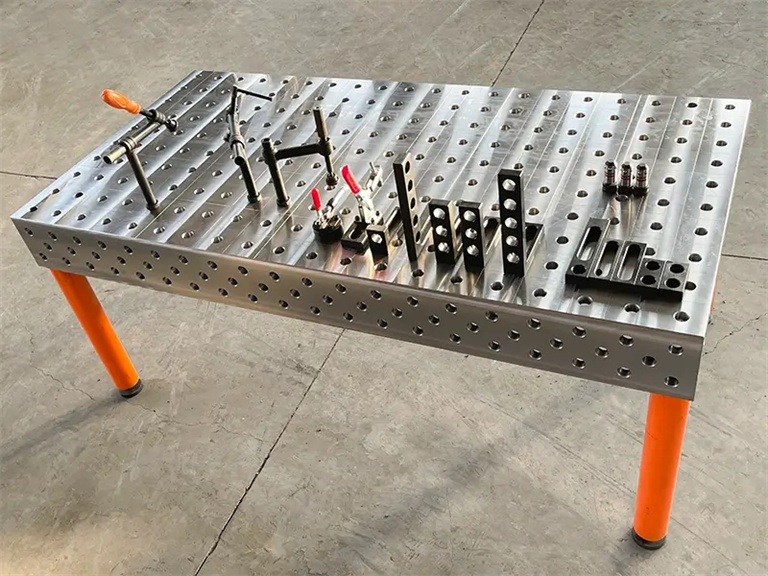

5.Support legs

The number of auxiliary supports legs of 3D flexible welding table should be determined according to the size of the welding table and application requirements. However, the auxiliary support legs position during the verification and use of the welding table should be the same as the design drawing, which determines the reasonable layout of the welding table’s support legs.

6.Appearance

● Check the appearance first when the user purchases 3D Welding Table. A good product starts with details. The appearance is free of sand holes, high processing accuracy, good finishing and well-preserved welding workbench is a relatively good product.

● Check all the working surfaces by the deep caliper, if all the holes diameter and center spacing are the same, then the quality is good.

● Check the quality of the 3D welding table by the installation of tooling fixture and table. If the tooling fixture is completely installed on it, and all the accessories are the same. Then the quality is good.

7. Cost

● Less floor space occupied: 3D welding table with accessories can reduce the storage space, because it only needs to use the combination of its standard modules to achieve accurate positioning and clamping of variety of products.

● Timeliness and economic: 3D flexible welding table fixtures can save the time of designing, manufacturing, and debugging tooling, and shorten the output time of new products. Although the price of 3D flexible welding table fixtures is high, the cost of custom-made welding table fixtures is also high, and the utilization rate is low, and the idle time is long.

● Low labor cost: The operation of 3D Welding table fixtures is simple, and through simple training, ordinary technicians can operate it immediately. A major feature of 3D flexible welding table fixtures technology is “flexibility”, that is, one set of fixtures can produce several or even dozens of sets of products. The use of different types of fixtures shortens the time for product research and saves a lot of manpower and material, while increasing the working efficiency, also reduce the production cost.

● High assembly accuracy and flexibility: There are D16 or D28 holes on 3D flexible welding table, locating tooling, support tooling and positioning tooling every 50mm or 100mm hole spacing. The tolerance of the hole spacing of any hole is less than 0.02mm. According to the structure of the workpiece, a complex and accurate tooling combination can be completed in a short time through interchangeable tooling to achieve positioning.

We are specialized in 3D Welding Table with fixtures. If there is any inquiry about that, please feel free to give us a call at +86-18951166013 or email us by sales@tiptopmfg.com for a formal quote and talk to LETIPTOP expert to get the support.