Laser Welding Machine

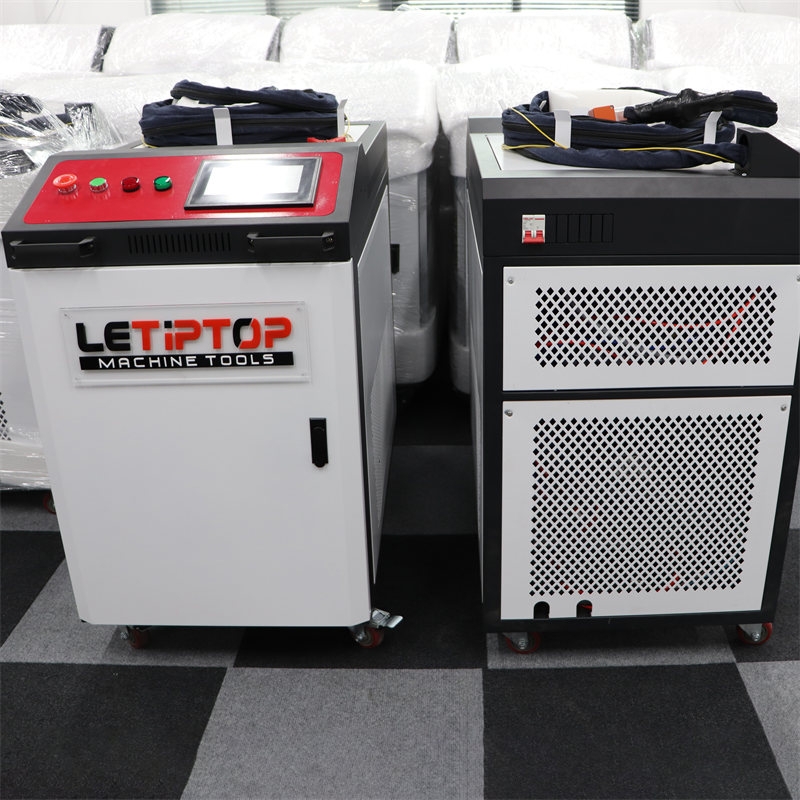

LETIPTOP Laser Welding Machine can improve your welding efficiency to achieve various angles of welding. It enables dramatically faster welding, is easier to learn and operate.

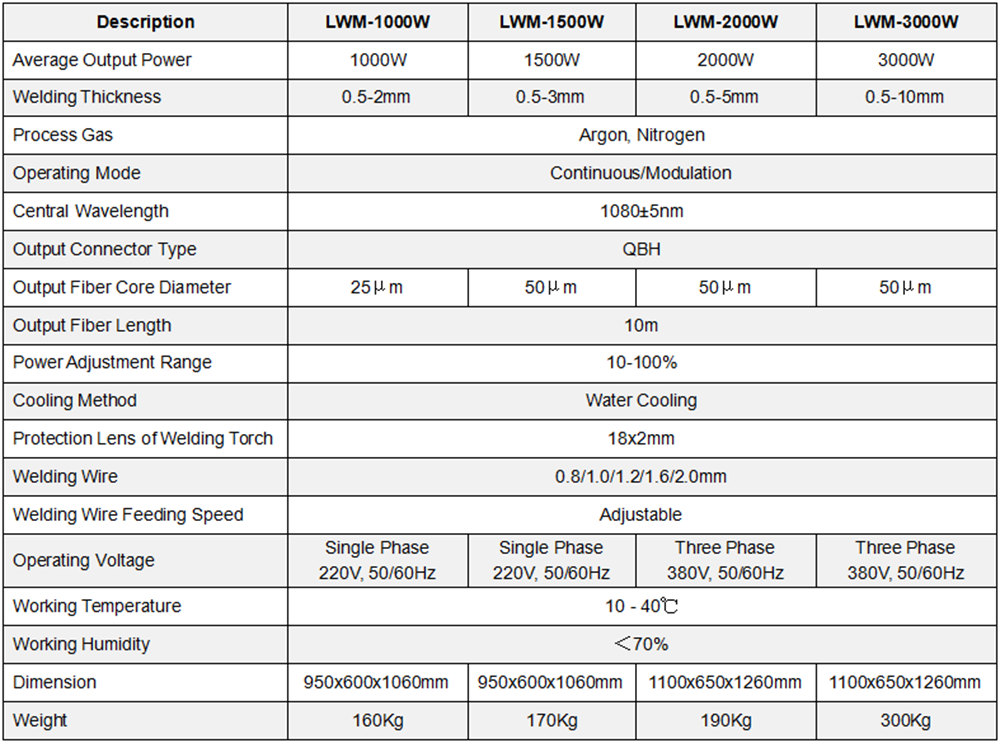

● 1000W, 1500W, 2000W and 3000W Laser Source

● Welding thickness upto 0.5-10mm

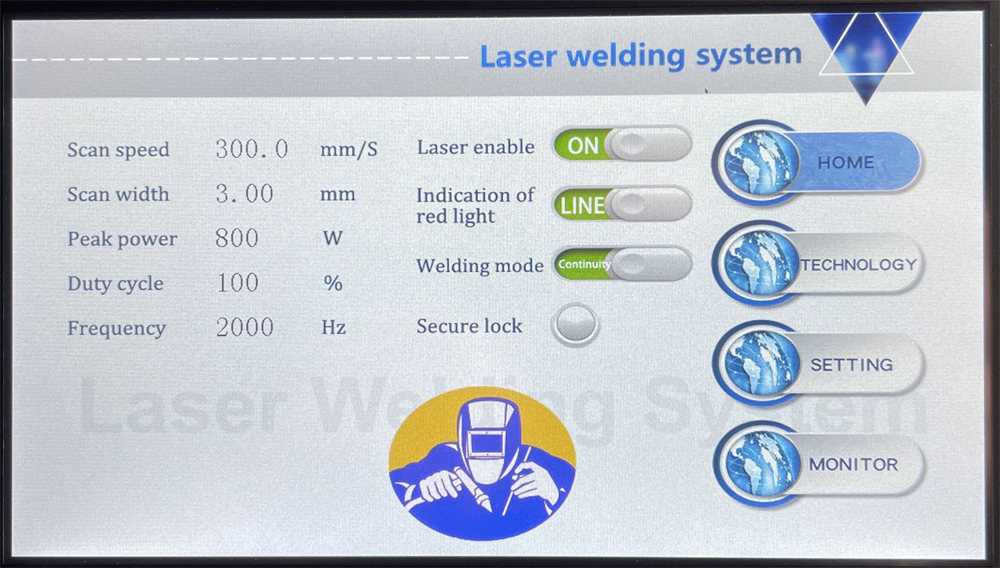

● Multilanguage Touch Screen Controller

● Water Chiller

● Handheld Laser Torch

● Automatic Welding Wire Feeder

Description

Laser Welding Machine

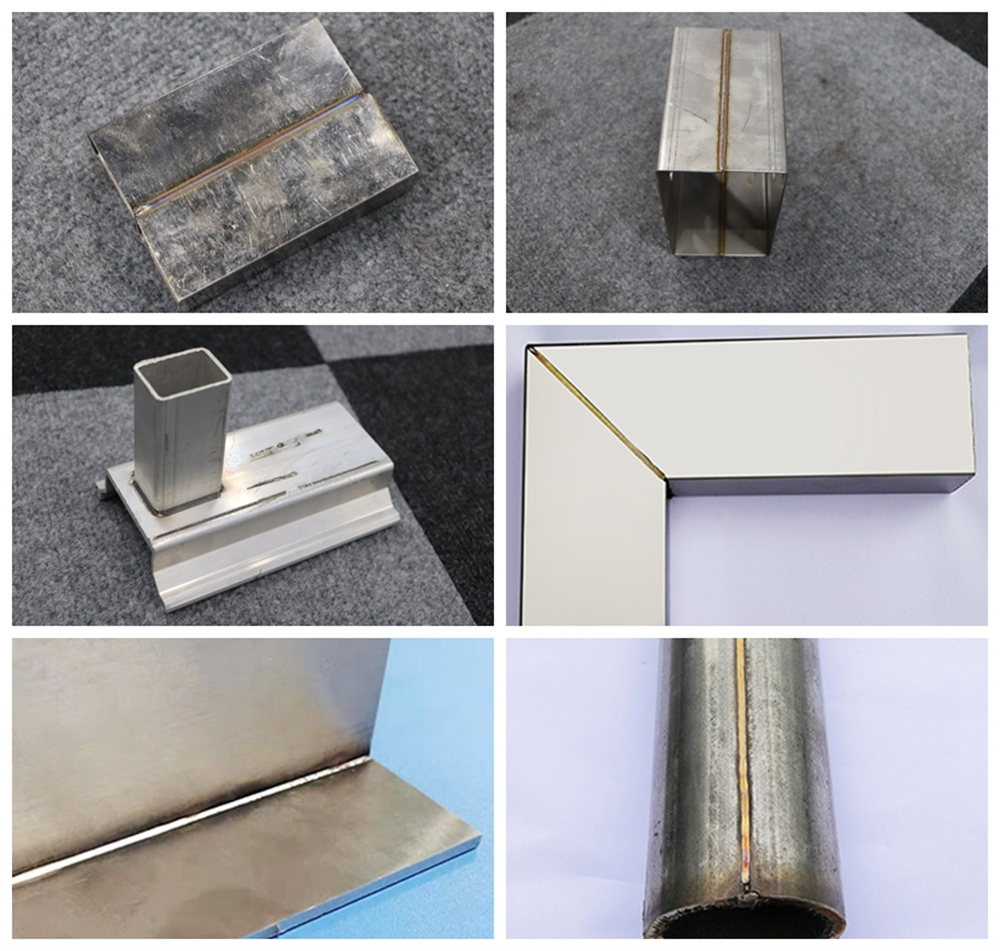

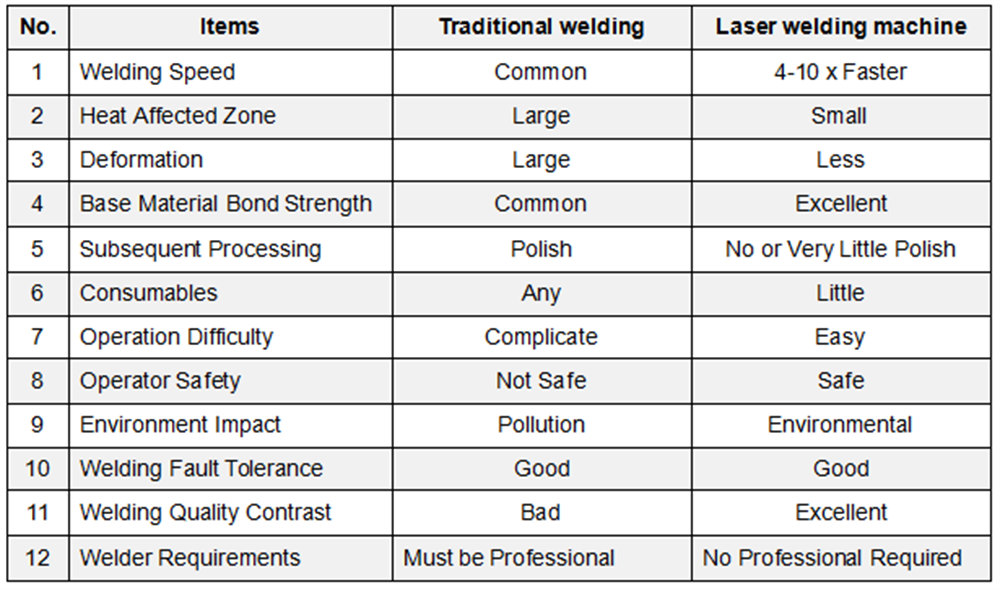

Along with the development of fiber laser source, hand-held laser welding machine was widely used and changed the industrial welding market by making it much simple for different angle and welding processing like spot welding, seam welding, tailored welding, overlap welding, T-profile welding, Internal/external corner welding. It could completely replace the application of traditional arc welder and electric welder technology in thin stainless steel, iron sheet, aluminum plate, copper and other metal sheet.

- Handheld Laser Welding Machine 1000W, 1500W, 2000W, 3000W.

- It is capable of welding different materials, such as stainless steel, iron sheet, aluminum plate, copper, and other metal sheet welding in 0.5-10mm thickness.

- Unskilled worker can get started in 10 minutes. Handheld laser welder speed is 4-10 times faster than the traditional TIG/MIG welding.

- Smooth and beautiful, which reduces the subsequent grinding process and saves time and cost by laser welder.

- High quality welding of thick, thin and reflective metals without distortion, deformation, undercut or burn-through.

- Variety type of welding nozzle can achieve various angles of welding.

- Touch screen controller support Multilanguage: Chinese, English, Japanese, Korean, Russian, German, French and Latin.

- Intelligent temperature control, chiller water cooling.

- The Auto wire feeding handheld welding machine can weld parts with wider gap.

- Nitrogen or argon shielding gas is demanded for welding.

Combined Laser Welding Machine and Welding Table to use, it will improve your working efficiency. Give us a call at +86-18951166013 or email us by sales@tiptopmfg.com for a formal quote on the Laser Welding Machine and talk to LETIPTOP expert to get the support.

Parameter

Configuration

1.Fiber Laser Source

Interactive control system makes the light spot larger, the welding seam better formed.

Excellent beam quality, high energy density and wide modulation frequency.

100,000 hours of lifetime, free maintenance, Low energy consumption.

2.Touch Screen Controller

Interactive control system

Support for multiple languages

Auto layout optimization, ensure high speed operation of whole machine.

3.Welding Torch

Hand-held welding mode, light and flexible.

Professional fiber laser cutting head

Through the connection with the laser, through the completely sealed optical channel in the cavity, an energy spot is formed

Variety Welding Nozzle used for spot welding, seam welding, tailored welding, overlap welding, T-profile welding, Internal/external corner welding.

4.Cooling Chiller

Industrial water chiller

Cooling the laser and the laser head

High cooling rate, which can weld fine weld structure and good joint performance.

5.Automatic Wire Feeder

No consumables, small size, flexible processing, low operating and maintenance costs.

Software controlled, adjustable wire feed speed

Filling the welding seam and increasing the welding strength

V and U type wire feeder wheels for selection.

Labor Cost Saving

Related products